Zero Infrastructure Bluetooth Tracking: Turning Your Frontline into a Visibility Network

The most significant barrier to true supply chain visibility is the capital cost of covering the entire network.

3 min read

Maya Ahluwalia

Dec 16, 2025 5:47:27 PM

Maya Ahluwalia

Dec 16, 2025 5:47:27 PM

Asset tracking has traditionally been about location. Knowing where an item was last seen, when it arrived at a facility, or when it left a depot has been enough for basic operational visibility.

But for many supply chain and logistics teams, this is no longer sufficient. When goods are damaged, delayed or rejected, the real question is rarely where an asset was, but what happened to it while it was moving.

This is where AI-enabled Smart Beacons begin to change the role of asset tracking, shifting it from location-only reporting to continuous insight into condition and handling across the supply chain.

Why location data alone isn’t enough

Most tracking systems rely on fixed checkpoints: warehouse doors, scanning portals or reader infrastructure installed at known sites. Between these points, visibility often drops away entirely.

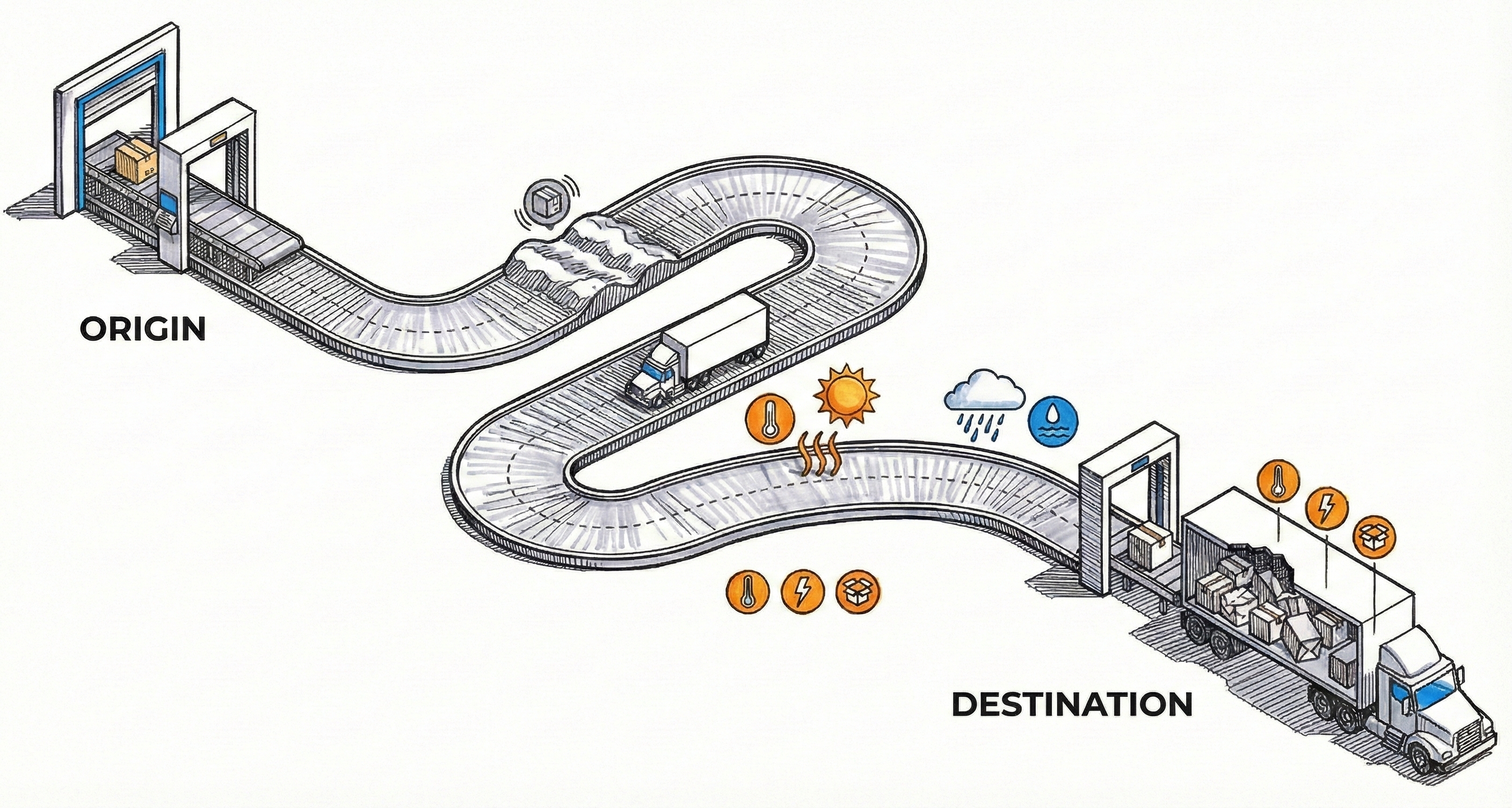

This gap creates real operational risk. Assets can be dropped, shaken, mishandled in transit or be exposed to temperature and environmental conditions outside of acceptable limits. These events may only become apparent hours or days later, when damage is discovered, quality checks fail or disputes arise with carriers and partners.

What supply chain teams increasingly need is in-transit visibility: insight into what is happening to assets between nodes, not just confirmation that they eventually arrived.

Smart Beacons are more than location tags

Modern Smart Beacons are far more than simple Bluetooth transmitters. They are designed to operate autonomously, carrying multiple onboard sensors and enough local storage to continuously log data throughout an asset’s journey, even when completely offline. Built for ultra-low-power operation, they can run for years on a single battery.

When connectivity becomes available, Smart Beacons securely synchronise their stored data using reliable, secure two-way communication, supporting remote configuration and updates along the way. This approach ensures that nothing is lost during transit.

The result is a detailed, end-to-end picture of an asset’s condition and location, captured directly on the device without the need for fixed infrastructure.

Adding AI to an already intelligent device

Sensor data collected by Smart Beacons can either be logged and data synced at a later date or transmitted to the cloud in real-time for analysis. By introducing AI, Smart Beacons can now also interpret sensor data on the device itself.

AI models running locally on the Beacon can recognise meaningful patterns in real time, such as sustained movement, idle periods or shock events.

The result is higher-quality data, lower transmission overhead and insights that are immediately actionable, without sacrificing battery life or requiring constant connectivity.

A real-world Smart Beacon tracking example

In this walkthrough, we show a package tracking application using Blecon Smart Beacons that travel with our equipment to global tradeshows.

These Beacons move through airports, vehicles and event venues. Rather than just providing a location ping, they build a history of the journey. They continuously monitor and log environmental data like temperature and humidity. Because Blecon supports reliable, secure 2-way data transfer, this history is stored on the device while in transit, even during flights or remote legs of the journey and automatically synchronised to the cloud over the Blecon Network when connectivity is restored.

Simultaneously, AI processes the accelerometer data. Instead of trying to store massive amounts of raw motion data, the Beacon identifies specific patterns, like "in motion" or "hard drop", in real time. The result is a complete, gap-free record of the asset’s status.

For frontline teams, scanning a Smart Beacon with a device provides an additional way to inspect an individual package on the spot, surfacing the same journey and handling information when it’s needed most.

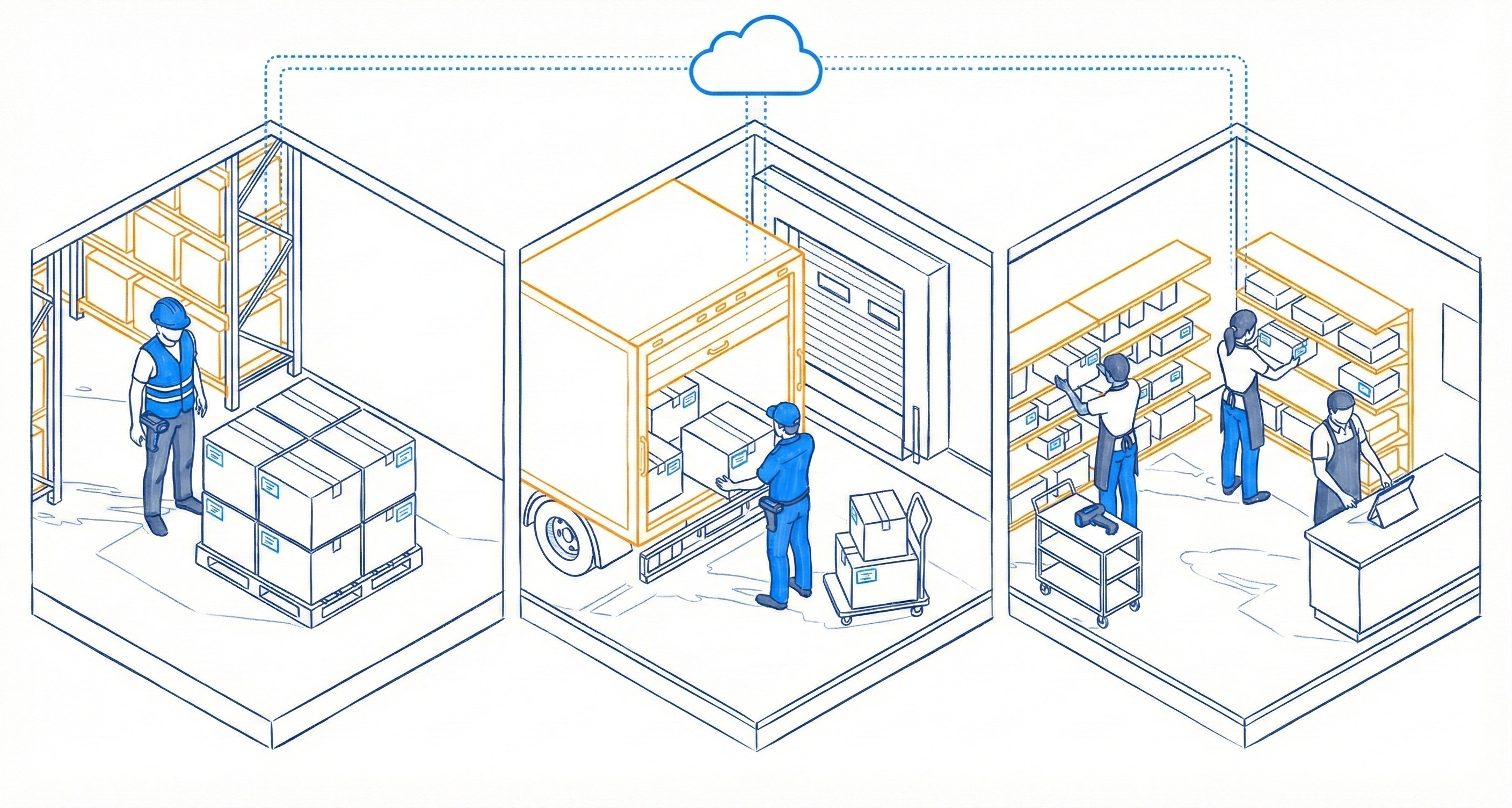

Importantly, all of this works without installing gateways or fixed infrastructure. Phones, tablets and other frontline devices act as roaming Blecon Hotspots, keeping assets connected wherever they go, including in the “messy middle” of the supply chain.

Why AI matters for asset tracking at scale

Supply chains rarely operate within a single organisation or a single environment. Assets move across partners, subcontractors, vehicles and shared facilities, where deploying dedicated infrastructure is often impractical or politically difficult.

Because Smart Beacons are already designed to operate autonomously, AI fits naturally into this model. AI runs on the device itself, allowing meaningful events to be detected as they happen, not reconstructed later from incomplete data.

For operations teams, this means richer visibility across the full journey, without introducing new infrastructure projects, complex integrations or increased operational overhead.

From tracking to operational insight

With AI-enabled Smart Beacons, asset tracking becomes more than a record of movement and environmental status.

Teams gain insight into how assets are handled in transit, enabling earlier intervention, better accountability and more informed decision-making. Over time, this data also provides objective evidence to support quality reporting, compliance requirements and discussions with logistics partners.

For use cases such as high-value shipments, returnable transport items, cold-chain logistics or sensitive equipment, this added layer of intelligence can significantly reduce loss, waste and operational friction.

How we made Smart Beacons smarter

If you’re interested in how this was implemented across Blecon Smart Beacons using Nordic Semiconductor’s Custom Neuton models and Memfault OTA, watch the walkthrough in this video:

For more information on Smart Beacons and their capabilities:

📖 Download The Evolution of Smart Beacons Whitepaper

Follow us on LinkedIn or subscribe to our newsletter for product updates and insights.

The most significant barrier to true supply chain visibility is the capital cost of covering the entire network.

For years, supply chain and logistics operators have accepted a persistent "black hole": the moment assets leave the warehouse, visibility vanishes....

Asset tracking has traditionally been about location. Knowing where an item was last seen, when it arrived at a facility, or when it left a depot has...